3D Printed Aviary Takes Flight with Simplify3D

Anyone who has ever created their own design knows the thrill of seeing their idea come to life. This is what happened for Vicky Somma of Virginia, USA. After getting an idea to design a charm for a favorite locket, Vicky, a programmer by trade, taught herself 3D design software Blender and used Shapeways to print her design. As she put it, “That was enough to get me addicted to 3D printing.” She has created dozens of different 3D designs, including an ornament that won the White House 3D Printed Ornament Competition in 2014.

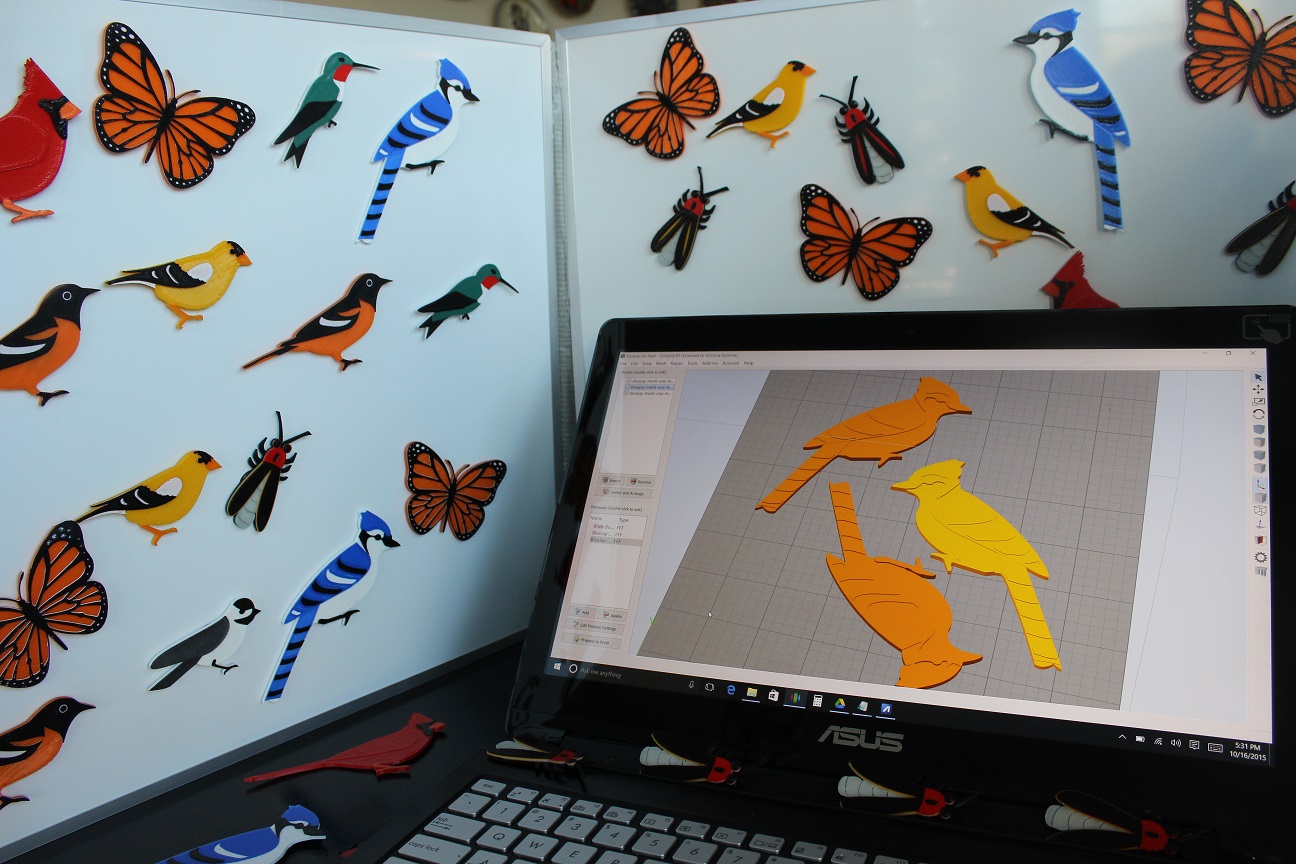

Vicky had been doing all of her printing via Shapeways until, in April 2015, her family surprised her with a MakerGear M2. With a 3D printer and a Simplify3D license of her very own, Vicky’s love of 3D printing only grew! Now she was able to design an object, print a prototype, iterate and perfect it. Although her early designs and prints were mostly gifts for family and friends, she soon moved on to designing decorative magnets, coasters, ornaments, and other keepsakes to sell on Etsy.com and local craft fairs.

Her largest body of work is what Vicky refers to as her “3D printed aviary.” Although her printer only has a single extruder, she figured out a creative solution to print with multiple colors. Taking inspiration from fellow Simplify3D user Joel Telling, she uses two unique software features to create multi-colored objects with a single-extruder printer. First, she creates multiple print processes within Simplify3D, one for each filament color.

The Layer Modification settings allow her to tell the printer to start or stop a process at a certain height. For example, take her monarch butterfly design: the first process would print the first few millimeters in orange, then stop so Vicky can change filament. The second process would print the next few millimeters in white, and so on until the object is complete.

The Layer Modification settings allow her to tell the printer to start or stop a process at a certain height. For example, take her monarch butterfly design: the first process would print the first few millimeters in orange, then stop so Vicky can change filament. The second process would print the next few millimeters in white, and so on until the object is complete.

According to Vicky, this capability has been a game-changer. “Before, I would manually pause the prints to change filament colors, which meant I had to stay pretty closely tethered to the printer (less than optimal when you are parenting small children). Now I let my process run and finish on its own, and I start the next color on my time. It’s made me a much more engaged mother to my 4-year-old and my 2-year-old!”

In addition to earning some extra income by selling her creations, learning 3D design and printing has been a life-affirming experience for Vicky. “It feels empowering to me, where everyone can be a creator.” With this technology becoming accessible to more and more people, Vicky has some advice for any 3D printing novices out there. She advises keeping a spreadsheet to document each print to help you remember what worked and what didn’t. It is also a good idea to save your successful factory files within Simplify3D so you can easily print them again.

Her most important words of wisdom? “First, don’t be afraid of failed prints. This is not a medium to be afraid of failures. This is a medium to embrace failure! Everyone has them. Everyone. Even super-high tech companies with industrial printers have them. Still afraid of failed prints? The only sure-fire technique I’ve found — get yourself a toddler. They don’t care if your overhangs are sloppy or if you have a stringy print. They’ll play with everything — good prints, bad prints, rafts, support material, skirt remnants, you name it. Everything is a successful print to a toddler.”

Her most important words of wisdom? “First, don’t be afraid of failed prints. This is not a medium to be afraid of failures. This is a medium to embrace failure! Everyone has them. Everyone. Even super-high tech companies with industrial printers have them. Still afraid of failed prints? The only sure-fire technique I’ve found — get yourself a toddler. They don’t care if your overhangs are sloppy or if you have a stringy print. They’ll play with everything — good prints, bad prints, rafts, support material, skirt remnants, you name it. Everything is a successful print to a toddler.”

Have interesting prints like Vicky’s that you want to have us spotlight? Email us at stories@simplify3d.com. Want to learn more about the features in Simplify3D that can help you achieve amazing 3D prints? See what the software can do.

Have interesting prints like Vicky’s that you want to have us spotlight? Email us at stories@simplify3d.com. Want to learn more about the features in Simplify3D that can help you achieve amazing 3D prints? See what the software can do.