Engaging Students with New Makerspace Program

Nucor Detailing Center, located in Norfolk, Nebraska, has just started the second year of a new educational outreach program that introduces 3D printing technology to 7th and 8th grade students. The program features the creation of several Makerspace facilities, which include 3D printers powered by Simplify3D Software. In 2018, the program reached five different junior high schools, providing over a thousand students with access to new technology and learning experiences.

The Creation Station Program

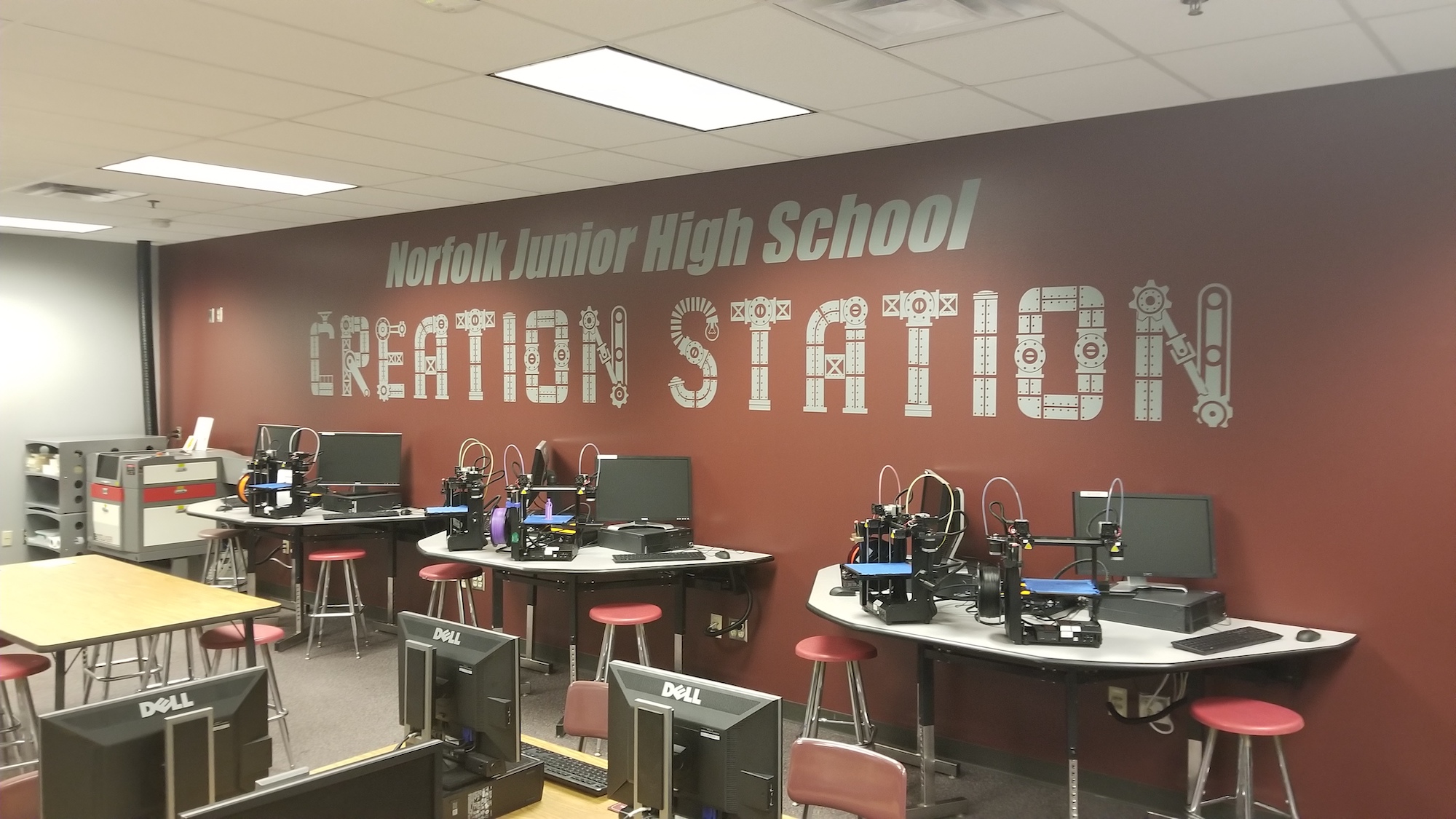

After receiving the Nebraska Developing Youth Talent Initiative grant, the Nucor Detailing Center (NDC) and its local partner schools applied the $125,000 towards building “Creation Stations”, a permanent makerspace in Norfolk Junior High School, and a mobile makerspace to provide equipment to the other four rural schools in Stanton, Battle Creek, Pierce, and Madison. NDC Trainer, David DeCarolis, says that these creation stations provide students with access to software and “age-appropriate manufacturing equipment, including 3D printers, laser engravers, CNC machines, vinyl cutters, and embroidery machines.” The program also includes staff training for teachers and presentations for students by Nucor staff to ensure both teachers and students know how to properly use the equipment.

After receiving the Nebraska Developing Youth Talent Initiative grant, the Nucor Detailing Center (NDC) and its local partner schools applied the $125,000 towards building “Creation Stations”, a permanent makerspace in Norfolk Junior High School, and a mobile makerspace to provide equipment to the other four rural schools in Stanton, Battle Creek, Pierce, and Madison. NDC Trainer, David DeCarolis, says that these creation stations provide students with access to software and “age-appropriate manufacturing equipment, including 3D printers, laser engravers, CNC machines, vinyl cutters, and embroidery machines.” The program also includes staff training for teachers and presentations for students by Nucor staff to ensure both teachers and students know how to properly use the equipment.

David explains, “The goal of the program is to introduce junior high students to drafting and manufacturing career skills. The long term goal is to strengthen the future manufacturing, IT, and drafting workforce in Northeast Nebraska.” He also shares that after just one year, surveys indicate an increased interest in manufacturing among students.

Using Simplify3D in the Classroom

NDC purchased eleven Makergear 3D printers along with Simplify3D software licenses for their Creation Stations, because “it replicates the design and manufacturing process that is at the heart of modern fabrication. Additive manufacturing is a rapidly growing industry that will require workers with the 3D modeling skills, which are being introduced along with the 3D printers.”

NDC purchased eleven Makergear 3D printers along with Simplify3D software licenses for their Creation Stations, because “it replicates the design and manufacturing process that is at the heart of modern fabrication. Additive manufacturing is a rapidly growing industry that will require workers with the 3D modeling skills, which are being introduced along with the 3D printers.”

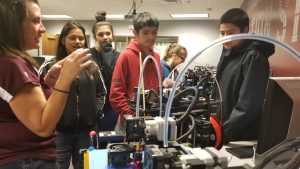

Using 3D printing has had a positive impact on classroom engagement. “3D printing is an easy way to generate excitement with students in many grade levels and varying interests. The sound and movement of the printers spur the interest and curiosity of the kids. Once they are focused on 3D printing, it becomes easier to have discussions about additive manufacturing and careers that use this technology,” David states.

Using 3D printing has had a positive impact on classroom engagement. “3D printing is an easy way to generate excitement with students in many grade levels and varying interests. The sound and movement of the printers spur the interest and curiosity of the kids. Once they are focused on 3D printing, it becomes easier to have discussions about additive manufacturing and careers that use this technology,” David states.

According to David, bringing 3D printing into the classroom has two primary challenges – print reliability and print time. He notes that they have solved the print reliability issue with quality hardware and software, because the “3D printers’ performance is only as good as the machine code created by the slicing software.” He adds, “We have tried other slicers in the past and have found that none compare to Simplify3D when it comes to ease of use and functionality. The students are able to quickly learn the workflow to process their 3D modeled objects by using the Simplify3D tools. This contributes to a higher success rate for fabricating 3D prints.”

Due to classroom sizes, schools often struggle to find enough time to allow all the students to print their models. David says that the program addresses this issue by providing “multiple 3D printers in the Creation Stations. Along with multiple machines, it is essential to have software like Simplify3D that helps to minimize print time. With our Makergear printers and Simplify3D software, we are able to load multiple models, print in two colors simultaneously, and even use the dual extruders to print two identical objects at the same time, which doubles our print speed.”

Due to classroom sizes, schools often struggle to find enough time to allow all the students to print their models. David says that the program addresses this issue by providing “multiple 3D printers in the Creation Stations. Along with multiple machines, it is essential to have software like Simplify3D that helps to minimize print time. With our Makergear printers and Simplify3D software, we are able to load multiple models, print in two colors simultaneously, and even use the dual extruders to print two identical objects at the same time, which doubles our print speed.”

Preparing Students for the Future

NDC and its partner schools eagerly look forward to expanding the program in the new school year. With additional funding from Nucor, the program will focus on establishing permanent Creation Stations in the four rural schools, instead of sharing a single traveling makerspace between the schools. This will give the four schools more frequent access to equipment, as they will no longer have to wait for the mobile makerspace to cycle through all of its rotations. NDC and its partners enjoy watching the students’ excitement and interest in manufacturing grow, and anticipate a stronger manufacturing and IT workforce as these students mature, to meet the demands of these quickly developing fields.

NDC and its partner schools eagerly look forward to expanding the program in the new school year. With additional funding from Nucor, the program will focus on establishing permanent Creation Stations in the four rural schools, instead of sharing a single traveling makerspace between the schools. This will give the four schools more frequent access to equipment, as they will no longer have to wait for the mobile makerspace to cycle through all of its rotations. NDC and its partners enjoy watching the students’ excitement and interest in manufacturing grow, and anticipate a stronger manufacturing and IT workforce as these students mature, to meet the demands of these quickly developing fields.

Simplify3D is being used by educators and students all over the world to improve student engagement and prepare students for jobs in design, manufacturing, engineering, and more. If you are interested in how you can bring Simplify3D to your own classroom, please visit our Education Page. If you have a story of how you are using Simplify3D in your own classroom, business, or community, we would love to hear about it. Share it with us at stories@simplify3d.com.