Massive Build Plates for Hunley and Hubble

Don Foley’s reputation as a master illustrator and visual journalist is well documented through an impressive body of work including memorable double-page layouts in National Geographic and Popular Science. Yet today, he is a man with an entirely new mission that includes 3D printing.

Thinking 3D printing could be an extension of his artistry, Don bought a 3D printer in early 2014 and proceeded to “tear it to pieces, improve a few things, and understand the mechanics inside-and-out”. However, he was “incredibly frustrated” after his first several attempts and sought better solutions online. That’s when Don learned about Simplify3D Software.

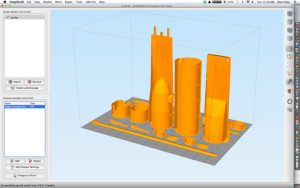

“Before I learned about Simplify3D, I had one failure after another. I would design an entire print bed of parts, but when one piece failed, the whole board was ruined. I was reduced to printing one part at a time and was going crazy”. In addition, Don says he was “forced to use rafts on all the small parts, but peeling them off was a pain and it took extreme amounts of time.” After switching to Simplify3D Software, Don fills the entire build plate with parts. He doesn’t use rafts and goes to bed confident that he’ll have a complete print bed about 17-20 hours later. In addition, he has control over the precision quality and detail he needs so that all his parts can be assembled smoothly.

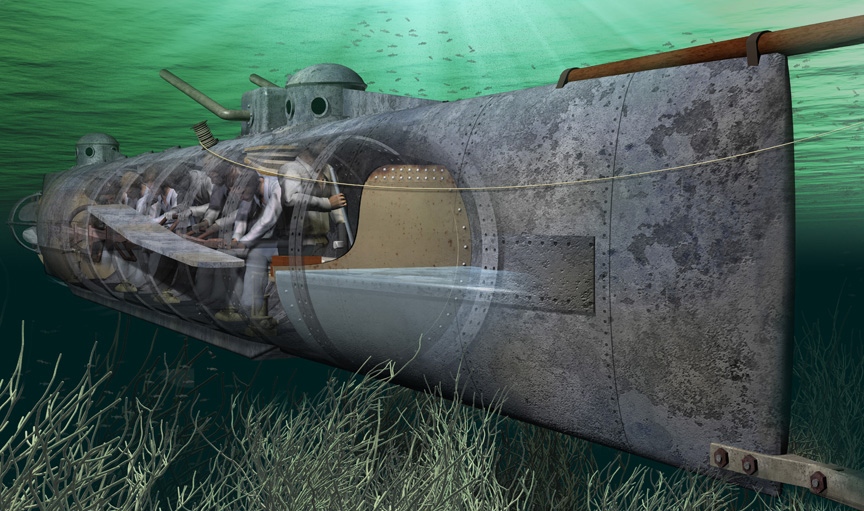

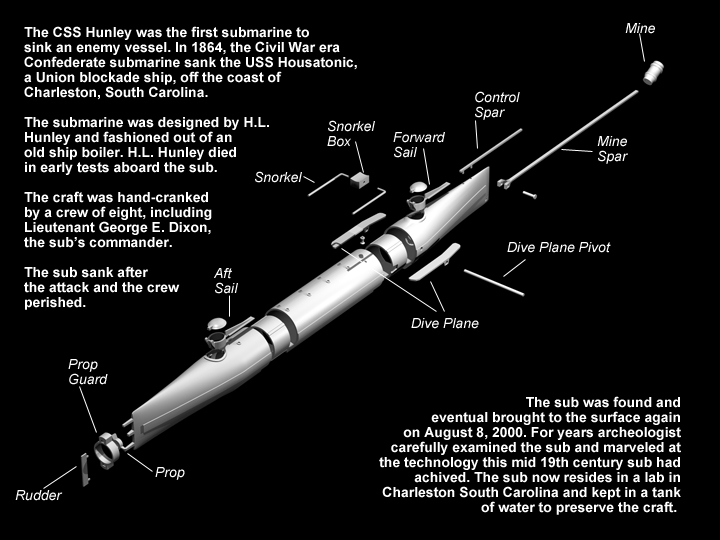

You’ll see an example of Don’s extensive build plate as he revisited the CSS Hunley, a confederate submarine that sunk off the coast of Charleston 150 years ago. Don covered the Hunley story for National Geographic in 2000, so he was intimately familiar with the design of the submarine. But as Don tells us, “3D modeling for illustration purposes is entirely different from 3D modeling for 3D printing purposes”. Don’s goal is a detailed model that will provide educational value and pure enjoyment for the person assembling the model.

As you can see, Don has added 3D printing files and visual assembly diagrams to his beautiful illustrations! Don is passionate about the educational value in this immersive approach because “when someone builds something and is part of the process, that is where real education happens.”

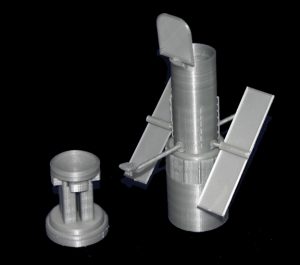

After realizing how 3D printing can expand the understanding of complicated structures, Don has progressed to other structures, including diagrams, models and 3D printed parts of the Hubble Telescope. We’re totally impressed by the efficiency of Don’s print bed and how well he has mastered the art of multi-part printing!

If you’ve read this far, we will reward you with a scoop! Popular Science will unveil Don’s 3D printing work in their June 2014 issue in an article called “A Jumbo Jet for a Fuel Starved Future”. The article includes Don’s illustrations, downloadable STL files and assembly diagrams so that you can build this visionary jet on your own 3D printer! This highly detailed model-making opportunity will be a first for the industry and potentially the birth of an entire new industry.

Don Foley attributes his success to “being in the right place a the right time”, but it’s clear that Don seizes an opportunity and pours himself into it. We can’t wait to see what is yet to come from Don Foley, and how 3D printing will be changed as a result.