Simplify3D Version 4.0 Print Contest Finalists

Thank you to everyone who provided submissions for the Simplify3D Version 4.0 Print Contest. We received many impressive entries! For the past 3 weeks, finalists have been selected based on the contest criteria listed here. Now it is time to choose the Grand Prize winner!

This is your opportunity to be involved in the vote:

1. Click each thumbnail below to see an enlarged image of the model.

2. Then click the ‘Vote Now’ button at the bottom of the page to select your favorite print!

The $500 Grand Prize winner will be announced on Tuesday, September 19th. Each Simplify3D license holder can submit one vote. Start looking below, and plan to be amazed!

Contest Finalists

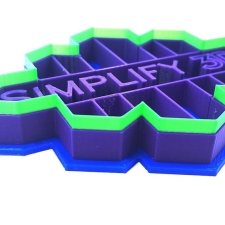

Simplify3D Cookie Cutter by Brandon Delph – This cookie cutter model uses several Simplify3D Version 4.0 Settings including various different infill settings, single extrusion walls, variable settings wizard, different color areas, and more!

Architectural Model by Garrett Faulkner – This massive architectural model nicknamed “The Beast” comes in measuring 42 x 18 x 8″ and took over 350 hours of print time to complete! It was printed with 0.2mm layer thickness and used new Simplify3D Version 4.0 bridging features.

Fantasy Castle by Luke Sideras – Using a rainbow roll of filament this colorful print took 57 hours to complete! The Simplify3D Variable Settings Wizard was used to print low infill for large base areas and a separate process for the towers with increased infill to provide better top layers.

Shoe by Shwetabh Jo – This fully functional shoe was printed with TPU filament using the Dynamic Gap Fill and Thin Wall Extrusion settings introduced in Simplify3D Version 4.0. Multiple processes were also used to print the sole of the shoe with 30% honeycomb infill and the upper body with 6% Grid Infill.

Battleship by Maurizio Castiglioni – This original model was inspired by the Italian battleship Littorio. Printed at 1/3000 scale, Simplify3D 4.0 small features and thin wall settings were used to print the small details. A 0.2 mm nozzle was used to print this model in ABS at 0.075 mm layer height.

Hairy Lion by Tony Akens – A remix of a the very popular Hairy Lion print, this entry shows off how Simplify3D new single wall extrusions gives this popular model a new look. You can see in the side by side picture below that the Hairy Lion model on the right was printed with significantly thinner hair.

Rings by Guy Vagman – These rings were designed using the Simplify3D Variable Settings Wizard and the newly featured option to combine “vase mode” with the layer by layer printing process. For a strong foundation Guy also used the new break-away raft feature.

Hockey Clock by Greg Takacs – This father-son project involved hardware, software, graphics design, CAD and 3D printing. The father-son team used Simplify3D single extrusion and thin wall features to get the small features of this print perfect.

Yo-Yo by Jason Preuss – This model was inspired by wax paper yo-yos that Jason played with as a kid. Using Simplify3D Version 4.0 Variable Extrusion the spiral walls that make up this Yo-Yo were printed much thinner with better durability than the original paper version!

Camera Case by Albert Kelnberger – This camera case was printed for the Raspberry Pi Zero and took advantage of several new Simplify3D 4.0 features including the Variable Settings Wizard, New Break-Away Rafts, and Dynamic Gap Fill. Check out the image for screenshots of the exact Simplify3D settings used.

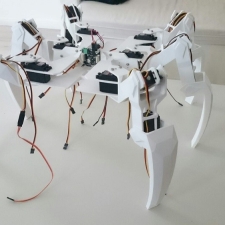

Hexapod by Alexander Wessling – This home made mechanical assembly of a Hexapod is an original design and used Simplify3D dynamic extrusion setting to print varying wall thickness between 1 and 2.5mm. The Internal structure was completely managed by Simplify3D.

Bridge by Frank Lenski – This bridge is modeled after the popular Te Rewa Rewa Bridge located in New Zealand. Used for testing in a wind tunnel, this model is over a meter long and was 3D printed using Simplify3D Variable Extrusion Sizing, Dynamic Gap Fill, and Improved Sequential Printing.